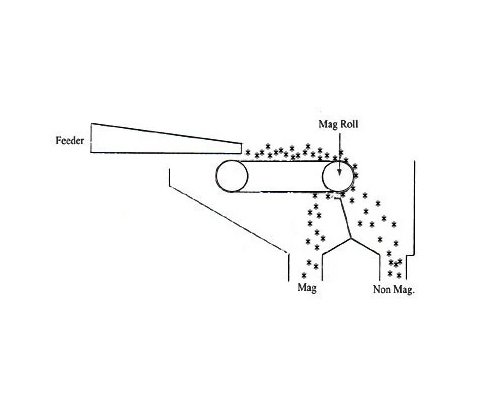

Magnetic Roll Separator

A short special fabric conveyor belt covers the magnetic roll and a tensioning idle roll driven by a motor. A feeder discharges material on the belt on continues controlled rate of flow at uniform layer thickness. The ferromagnetic and paramagnetic particles adhere to the belt while the non-magnetic particles flow freely off the end of the conveyor. The division of paramagnetic and non-magnetic adjusted by using a splitter plate located below the belt. It can be configured stacked in any number of passes to suit the user requirement.

Application:

The open design of the G.A.S allows both coarse and very weakly magnetic materials to be treated successfully. Proven dry process application includes material from 75 microns up to 100 mm (4 inch) particle size, at through outputs from 200 kgs to 60 TPH.

Technical Features

- Standard 2.5,2,1.5,1,0.75,0.5 and 0.25-meter wide magnetic roll. Also available in a laboratory scale model with readily interchangeable rolls of 100 mm length

- Supplied with a vibrating feeder to suit the roll width

- Simple conveyor belt tensioning and tracking system accessible at the sides of the machine

- Fixed or-variable speed roll drive options. Fractional HP motor having voltage and frequency to suit user